Communications have improved considerably in recent years thanks to the latest technological advances. Nowadays, we have much more efficient and faster devices in business and industrial environments. In some sectors, such as Medicine, having secure networks is essential to improve communication between professionals, patients, and users. Therefore, we are going to explain what the types of PROFIBUS are and how they work.

Contenidos

What is PROFIBUS?

The PROFIBUS protocol has gained great importance in the industrial sector because it improves the user experience. This technology was developed with the aim of offering intelligent and secure networks to provide more efficient communication with automated equipment. It is an initiative of the German government, which emerged in the 1980s and currently offers excellent performance.

Initially, this digital network standard offered the FMS (Fieldbus Message Specification) profile, but over time it fell into disuse due to technological advances. Nowadays, there is a more innovative proposal that allows more complex tasks to be carried out simply by pressing a button.

How does PROFIBUS work

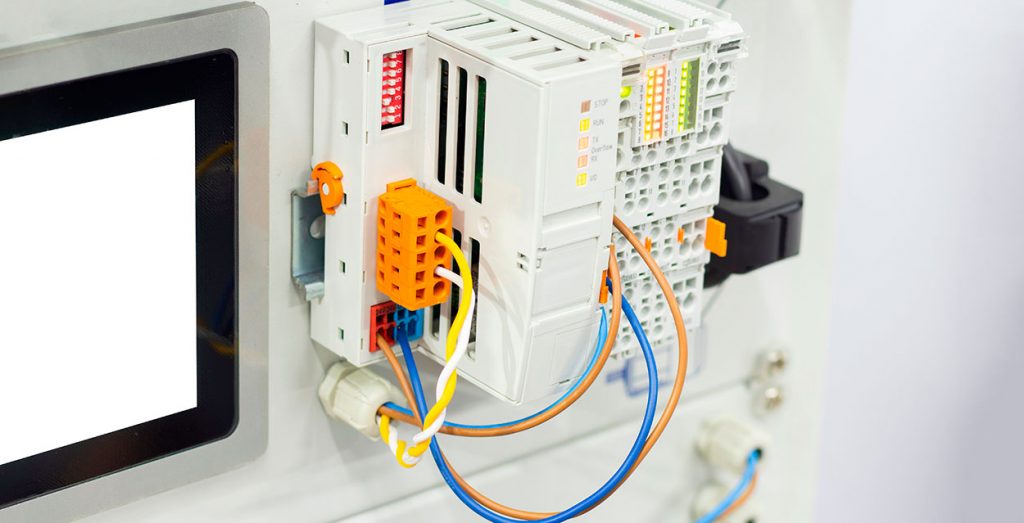

This communication system has been designed mainly for control in industrial processes. In addition to transporting data, it also promotes the interconnection of equipment with physical interface cards. Therefore, it is a network that uses master-slave access control.

It is a perfect communication system, because binary data signals are transmitted through a very simple and economical data bus. This AS Interface performs this transmission in cycles; however, parameters, alarms, or diagnostics are only transmitted when necessary.

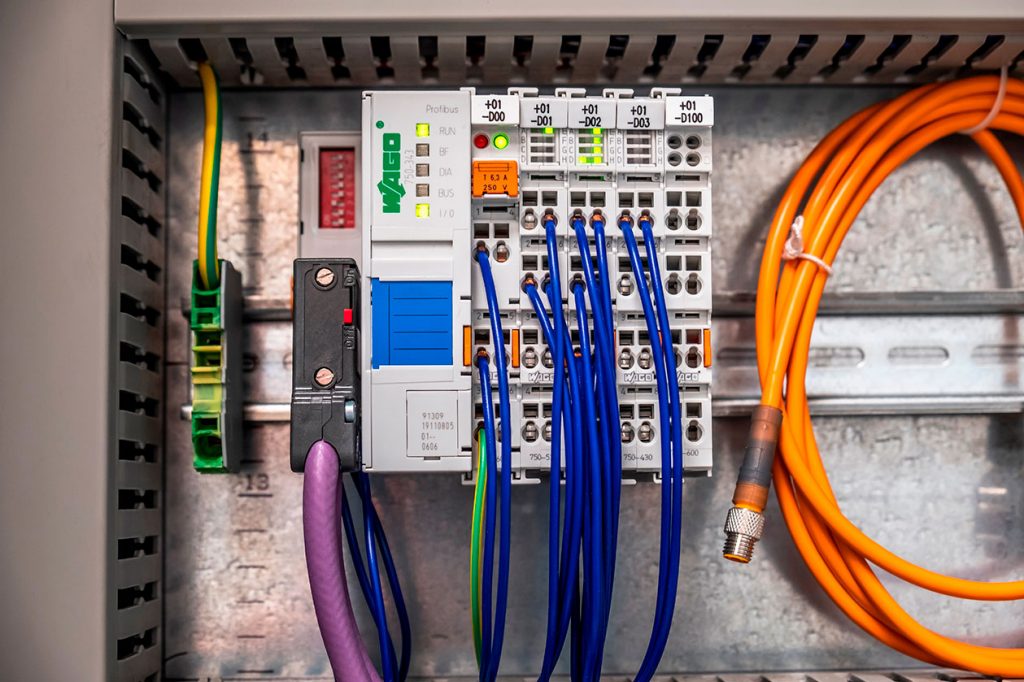

As for peripherals, such as I/O modules, drives, valves, or control panels, they operate through a very efficient real-time communication system: PROFIBUS DP or PA.

It is worth highlighting its mandatory integration in different corporate communication systems, such as Intranet, Internet, and Ethernet. This is possible thanks to the PROFINET protocol (Process Field Network), which has a very similar approach and consists of exchanging data between devices and controllers.

This technology plays a fundamental role in optimizing communication systems. The use of standardized and open protocols, in its two different versions, allows partial loads without being exposed to data loss. One of its advantages is its compatibility with other legacy systems, so its replacement is not mandatory.

Types of PROFIBUS

Over time, different types of PROFIBUS have been developed to adapt to current needs. For this reason, it is advisable to know which ones they are and their main characteristics in order to implement them successfully.

- PROFIBUS FMS. This option offers a wide range of functions compared to other solutions. It is a very useful tool for processing complex communications; however, nowadays it is being replaced by the Industrial Ethernet protocol.

- PROFIBUS DP. This solution was developed to improve communication between decentralized equipment and automation systems. It uses a standard interface in RS-485 communication or fiber optics, and only a couple of minutes are needed to transmit 1 kB of I/O.

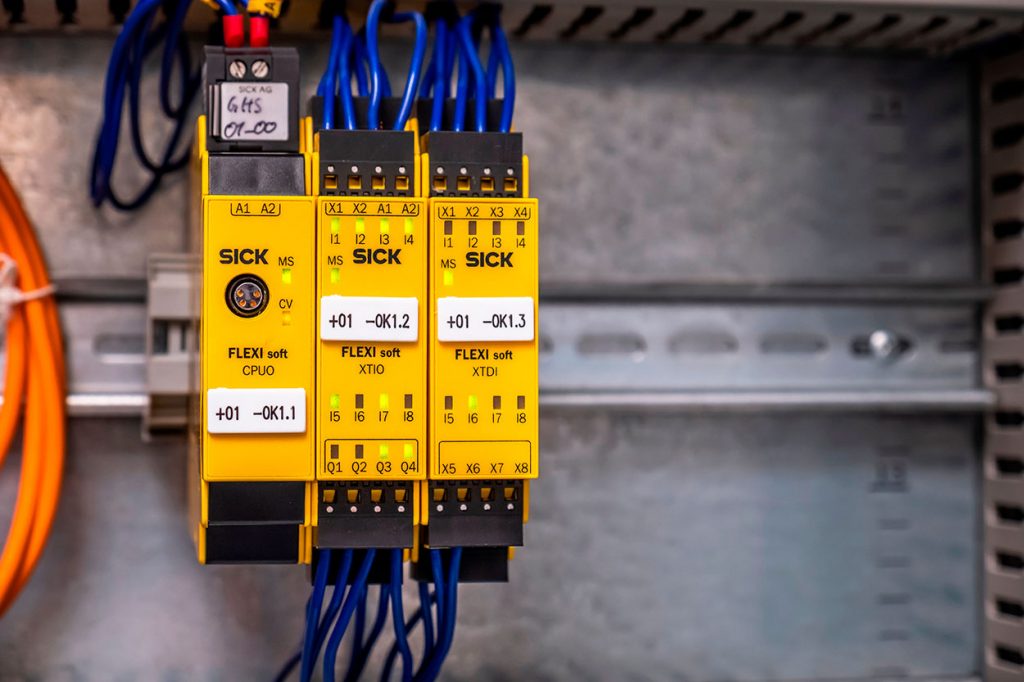

- PROFIBUS PA. One of its main features is the transmission of reliable information in variable states and its self-diagnostic capability. It also powers the equipment and allows connection and disconnection during operation without interfering with other stations.

- DP/PA Coupler. To connect a transmitter, converter, and positioner in a PROFIBUS DP network, it is necessary to use a DP/PA coupler. This is a twisted cable used as a power supply and data communication source to facilitate the installation and maintenance of each piece of equipment.

What are the benefits of using PROFIBUS?

This type of decentralized network is easy to implement in communication processes, no matter how complex they are. PROFIBUS is an industrial standard that has proven its effectiveness in process automation; for this reason, this investment is highly profitable.

- The ability to connect industrial devices without using cabling is one of its greatest advantages.

- In addition, installation costs are reduced by approximately 40%, since it is not necessary to manually connect these devices. For this reason, the costs associated with this configuration and its maintenance are considerably reduced.

- Another of its competitive advantages is the possibility of performing quick diagnostics to determine whether there is any problem with performance.

- Ultimately, fast and accurate diagnostics improve its capability.

How is PROFIBUS implemented in a system?

To achieve a successful implementation with full guarantee, it is necessary to assess certain aspects, such as correctly choosing the cabling; the results will vary according to its characteristics. It is also necessary to carry out an initial planning of the protocol, verify whether the configurations are compatible with the devices, install all the required adapters, and perform acceptance tests before validating it.

The correct configuration between the cabling and the different devices improves performance and stability. For this reason, before installation it is necessary to run simulations to identify whether there are any problems with cycles or response time. The final purpose is to avoid errors in industrial networks and verify that all the agents involved correctly fulfill their role.

If you have any questions about choosing these types of PROFIBUS, do not hesitate to get in contact with us. Advantencia is a Spanish company that belongs to ACE Business Group and has extensive experience in hospital communications. Our technology promotes comprehensive management to care for patients and users in these health centers and ensure proper operation.