Industry has changed a lot in the last decade, so much so that we can say it has faced another revolution related to communications and automation. Now, machines “talk” to each other and communicate with central systems, which means they need a protocol to do so and specific hardware. In this post, we explain everything you need to know about industrial communication buses.

Contenidos

What are industrial communication buses?

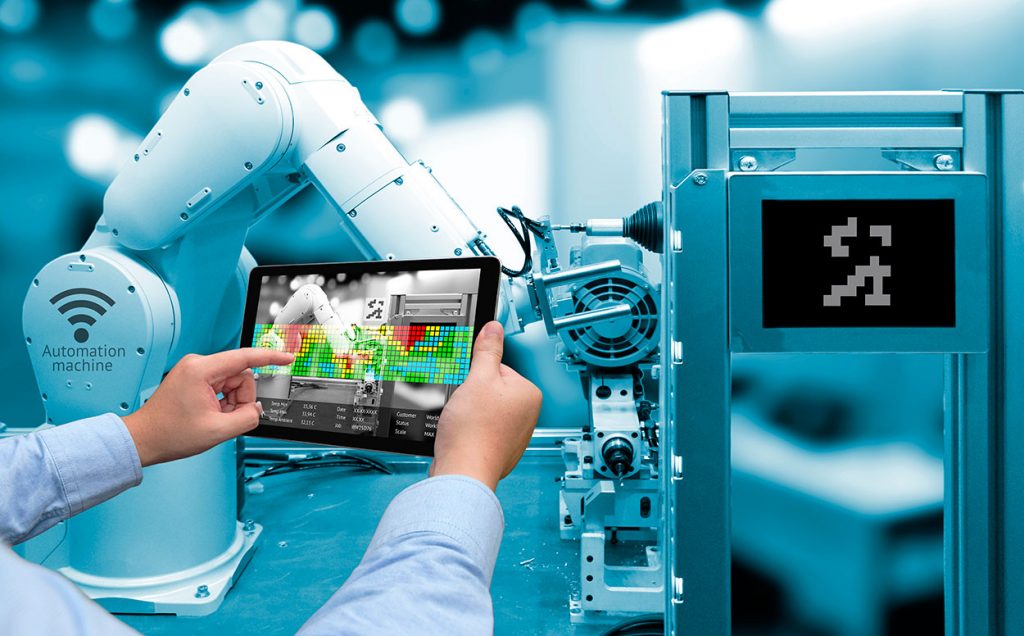

Industrial communication buses are nothing more than systems that make it easier for devices to communicate with each other and with control equipment, which allows many processes to be automated while also maintaining control over them.

At present, there are various technologies, both wired and wireless. When cables are required, there are specific types designed for complex environments, such as those where grease is handled or places where cables are subjected to tension, among others.

What are industrial communication buses used for?

These buses have several functions that allow them to control very complex industrial processes.

They integrate systems

Through buses, all network systems and control devices communicate with each other, making it possible to coordinate the actions they carry out. In fact, this is what allows industrial processes to be automated, limiting workers to supervising and controlling them.

Monitoring

With buses, monitoring production is very simple. This can be done from anywhere in the world, although generally there is always a control room where several workers are viewing the data and confirming that everything is running correctly.

Remote diagnostics

A connected machine can be accessed from anywhere there is a network connection. In this way, thanks to these communication interfaces, it is possible to diagnose faults without being physically present, which makes it easier for technicians to understand what is happening.

In fact, in some cases, necessary repairs can be carried out without even going to the factory, which extends the useful life of the equipment and ensures it is always operational without having to wait too long.

They provide flexibility

Configuring machines has never been easier. Thanks to control systems and equipment, it is possible to make the necessary changes to adapt the operation of each machine to current needs, achieving great flexibility.

How are industrial communication buses controlled?

Buses are controlled by distributing communications across several layers, since this makes them easier to manage, because one of their drawbacks is that they create a very complex network that is not easy to administer.

To do this, a hierarchy is established, with two communication directions that facilitate management: one horizontal and one vertical.

The first, the horizontal one, is adopted between devices locally, while the vertical one is carried out through networks and allows planning, visualizing machine data, managing production, etc.

Both communications, horizontal and vertical, connect to network nodes, which are interconnected with each other and send data whenever necessary.

In order to establish communications, a connection medium is required, which can be wired or wireless, the latter being preferred due to cost and space savings, as well as allowing machines to move without network cables getting in the way.

What are the most common industrial communication buses?

One of the problems surrounding communication buses is that there is no single standard. There are models that have become the most widely used, and although the sector has tried to make one of them the standard, the truth is that this has not been achieved.

For this reason, there is a large number of models, and the choice depends on the needs of each business where they are installed.

PROFIBUS

It is true that a single standard has not been established, but PROFIBUS almost is. It is used to communicate data in real time and is one of the most widely used fieldbuses worldwide.

Modbus

This is used when automating industrial processes, specifically when electronic devices are connected, always using a serial communication protocol.

It is one of the most common, and as in the previous case, it can almost be considered a standard communication protocol in industry.

Unlike PROFIBUS, this communication protocol is open and royalty-free, which makes it very easy to install and maintain, since all information about it is public.

CAN Bus

This protocol was developed for the automotive industry and is message-based, although it has now reached other sectors. In fact, it would be complicated to explain what current hospital management is without talking about the CAN Bus.

In this contact form you can ask your questions about how this CAN Bus is used in hospital machines.

AS-Interface

It is an open technology used by many automation devices and was designed to connect very simple devices such as sensors, actuators, push buttons, valve position sensors, etc.

Interbus

When a high transmission speed is required, this bus is the chosen one. It reaches up to 2 Mbps and is divided into several systems, allowing it to connect nearby users as well as others who are far apart, over long distances.

Specifically, it can interconnect up to 254 users regardless of the kilometers between them.

Industrial communication buses have made it possible for different manufacturing processes to go one step further, becoming fully automated and sending information in real time, both locally and to remote users.